VANCOUVER, British Columbia, Jan. 07, 2025 (GLOBE NEWSWIRE) -- West Red Lake Gold Mines Ltd. ("West Red Lake Gold” or the "Company”) (TSXV: WRLG) (OTCQB: WRLGF) is pleased to announce the results of the pre-feasibility study ("PFS”) prepared in accordance with National Instrument 43-101 - Standards of Disclosure for Mineral Projects ("NI 43-101”) for the imminent restart of its 100% owned Madsen Mine project in the Red Lake Gold District of northwestern Ontario, Canada.

West Red Lake Gold will hold a conference call on January 8th at 11:00am ET, followed by a question-and-answer period. To access the call, please register here: https://www.amvestcapital.com/webinar-directory/westredlakegoldmines010825. The webinar will be archived for viewing at www.westredlakegold.com

All dollar amounts in this news release are in Canadian dollars ($) unless otherwise indicated.

The effective date of the PFS is December 31, 2024, and a technical report relating to the PFS will be filed on SEDAR+ within 45 days of this news release.

Madsen Mine PFS Highlights:

- Strong Value Underlines Mine Restart Rationale: Post-tax net present value ("NPV”) (5%) of $315 million at a long-term gold price of US$2,200 per oz. reinforces the rationale to restart the Madsen Mine imminently based on this initial mine plan; potential for Madsen to grow beyond this initial plan with further definition and exploration drilling strengthens the rationale

- High Grade Mine: Diluted head grade averages 8.2 g/t gold

- Average Annual Production: 67,600 oz. gold per year over 6 years of full production, within a 7.2-year mine life

- Strong Free Cash Flows: $69.5 million average annual free cash flow from an operation with average total operating cost of US$919 per oz. and average all-in sustaining cost ("AISC”) of US$1681 per oz.

- Construction and Capital Investment to Mine Startup Substantially Complete. Bulk sample currently being mined; mill startup to process bulk sample planned in March; 21 km of modern underground development (since 2019) provides good mining access and represents significant time and cost savings

- Production Start Date: Q2 2025

- Actual Costs: The Company has been operating underground for 16 months and the mill operated in 2022, which enabled a PFS based on realized costs for most operating metrics.

- Significant Upside Potential: There are multiple opportunities to extend mine life and enhance the economic returns of the Madsen Mine, including 1.1 million ounces of indicated resource that remain outside of this initial mine plan, resource growth near reserves and existing infrastructure, discovering new high-grade, near mine zones that add to the mine plan such as the Upper 8 Zone, and using a higher reserve cut-off price (the PFS used US$1680 per oz.).

"Initial capital is low because the capital projects needed for restart are well advanced or already complete. That is unusual for a 'PFS-level' project, as is having already completed 58,000 metres of definition drilling and detailed engineering to define 18 months of mineable inventory on a stope-by-stope level.

"We are excited to deliver a PFS that solidifies Madsen as a rare high-grade gold mine starting production in 2025. We built a realistic and achievable plan for this first mining opportunity at Madsen that we are confident we can deliver and that will justify returning the mine to production. Beyond that, we strongly believe Madsen has potential to grow well beyond this initial plan in the coming years as we source new resources and reserves near existing infrastructure while also gaining access to the deeper parts of the system, where notable upside optionality remains untapped.”

The PFS was prepared by independent consultants SRK Consulting (Canada) Inc., with input from AllNorth Consultants Ltd (infrastructure), T-Engineering Ltd (backfill), Nordmin Engineering Ltd (shaft), Fuse Advisors (processing), Mining Plus (mine design support), and Knight Piesold (tailings and waste rock).

Economic Results and Sensitivities

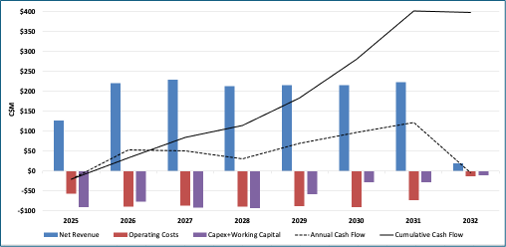

Table 1 summarizes the projected production and economic results of the PFS for this initial Madsen Mine plan. Figure 1 shows the Madsen Mine cash flow profile by year.

Table 1: Madsen Mine - Key Economic Assumptions and Results

| Mine Life | yrs | 7.25 |

| Total Ore Mined | million tonnes | 1.823 |

| Steady State Processing Rate | tpd | 800 |

| Average Head Grade | Au g/t | 8.16 |

| Gold Recovery | % | 95.7% |

| Average Annual Gold | oz / year | 67,600 |

| Total Payable Gold | oz. | 457,851 |

| Total Operating Cost | US$/oz | 919 |

| Long Term Gold Price | US$/oz | $2,200 |

| Gross Revenue | C$M | $1,480 |

| Net Revenue | C$M | $1,465 |

| Initial Capital | C$M | $44.1 |

| Sustaining Capital | C$M | $434 |

| Average AISC | US$/oz | $1,681 |

| Cumulative Net Cash Flow (pre-tax) | C$M | $392 |

| Cumulative Net Cash Flow (post-tax) | C$M | $391 |

| NPV (post-tax) | C$M | $315 |

| IRR (post-tax) | % | 255% |

| Discounted Payback Period | yrs | Less than 1 |

Upside Potential

The Madsen Mine project hosts probable reserves of 1.823 million tonnes grading 8.16 g/t gold, containing 478,000 oz. gold. This compares to an indicated resource of 6.9 million M&I tonnes grading 7.4 g/t gold hosting 1.65 million oz. gold, plus an inferred resource of 1.8 million tonnes grading 6.3 g/t gold hosting 366,200 oz. gold.

West Red Lake Gold sees two opportunities to potentially convert more of the Madsen Mine resource into reserves.

First, the PFS defines reserves using a gold price cut-off of US$1680 per oz.1 This highly conservative gold price cut-off resulted in significant portions of the indicated resource being excluded from the mineable reserve. Sensitivity analysis shows that increasing the cut-off price to US$1900 per oz. increases reserves sufficient to add approximately two years to the mine plan.

Second, there are many distal portions of the Madsen resource that would require access through un- or undertested areas with high geologic potential for mineralization. West Red Lake Gold plans to drill test these areas; success delineating mineralization in these gaps has the potential to transform additional resource areas into economic reserves while also growing the resource base. Notable underground expansion drilling is planned for 2025 from three key areas: 1) Connection Drift, 2) East Ramp decline targeting down-plunge North Austin, and 3) East Exploration Drive from 13L to access lower Austin and eastern extensions of main deposit.

The combination of delineating new mineralization in undertested gaps, extending known reserve areas, and converting more resources to reserves has the potential to add ounces and extend mine life via (1) reducing the access development needed per tonne of ore mined and (2) supporting increased flexibility between lower-cost Longhole Stoping ("LHS”) and Mechanized Cut and Fill ("MCF”). Currently, the PFS outlines 59% MCF and 41% LHS.

In addition, the PFS only considers four of the seven deposits that make up the Madsen resource (Austin, South Austin, McVeigh, and 8 Zone). Other deposits at the Madsen Mine site could potentially be included in a future mine plan, such as the Fork deposit where West Red Lake Gold recently identified a high-grade portion located 250 metres away from existing underground workings. The recent Upper 8 discovery also has potential to become a shallow zone of high-grade mineralization. Additionally, the Company owns the Rowan Project that is 80 km away by road and hosts indicated resources of 476,323 tonnes grading 12.78 g/t gold hosting 195,746 oz. gold and inferred resources of 410,794 tonnes grading 8.76 g/t gold hosting 115,719 oz. gold.

West Red Lake Gold sees strong potential to expand the Madsen Mine beyond the operation defined in this PFS if future drilling, engineering, and permitting demonstrates it is economic to include additional zones into an updated mine plan. The PFS is based on 800 tpd throughput; the Madsen Mill has nameplate capacity of 1,089tpd.

Mining

The mine will operate as a mechanized underground operation with a steady state production rate of 800 tonnes of mineralized material per day operating for 7.25 years.

Mining will be a combination of mechanized cut-and-fill (59%) and long hole stoping (41%). The minimum mining width is 2 metres. Average stope width varies with mining method from 3.2 metres to 7.2 metres.

Ore is moved to surface via a combination of ramp trucking and shaft skipping. Trucking will be utilised above 8 Level. Material from 8 Level and below will be trucked to a Main Shaft loading pocket at 12 Level and from there skipped to surface.

Rehabilitation of the Madsen Main Shaft is well underway. The PFS includes the cost for the continued rehabilitation and refurbishment of Madsen Main Shaft to allow for skipping from 12 Level. The Main Shaft is currently dewatered to 15 Level; dewatering will continue to allow for access to the lowest levels of the mine.

Once the mine is dewatered on 20 Level, a new shaft will be excavated to surface in two lifts using raiseboring methods. This Madsen East Shaft will supply ventilation to the lower reaches of the mine, allow for skipping of material and slinging of heavy equipment, and allow for possible future expansion at depth.

Steady state waste production is approximately 1,200 tpd. Care has been taken to optimize the backfill of waste rock into historic stopes and new excavations.

The existing Madsen mill contains a working Hydraulic Fill (HF) plant that the previous owners commissioned (but did not use). West Red Lake Gold will recommission the plant to pipe HF to the historic voids underground. HF is a way of backfilling underground workings using tailings from the mill, adding a binder (a low percentage of cement), and pumping the resulting slurry back underground. HF backfill provides an environmentally friendly way of disposing of tailings and provides a stable geotechnical environment for mining. Once the HF is decanted and cured, it is strong enough to mine immediately adjacent to, allowing the Company to optimize the extraction of ore around old stopes.

The mine is primarily ventilated via the Madsen Main Shaft and the West Ramp. The main fans are situated underground, on 12 Level. Air is downcast through the Main Shaft and is allowed to exhaust via the ramp. Once completed in year 4, the East Shaft will significantly enhance the ventilation to the lower reaches of the mine. A connection between the West and East ramps is being driven (the Connection Drift) that will assist in efficiencies for ventilation between the two districts. Currently, the East section of the mine (a much smaller section) is ventilated via the West through old workings. The air heater is situated near the Madsen Main shaft on surface.

Processing

At steady state operation, an average of 800 tpd of material will be processed in a plant that consists of primary crushing, followed by grinding to 80% passing 75 µm using a semi-autogenous grinding mill and ball mill. Gravity concentration will recover gold from the SAG screen undersize and ball mill discharge. Cyclone overflow will be thickened to 50% solids in a pre-leach thickener, then pre-aerated with oxygen followed by a 24-hour cyanide leach at a cyanide concentration of 150-170 ppm and a pH of 11.0 in five leach tanks. Gold in solution will then be recovered via carbon-in-pulp (CIP) adsorption in six CIP tanks with a residence time of five hours, followed by acid wash, elution, and refining to produce gold dore on site.

After cyanide destruction, the CIP tailings will be pumped to the tailings management facility initially. Starting later in year 1, a thickened tailings will be pumped into open stopes using a hydraulic backfill system.

The process plant gold recovery is estimated to average 95.7% over the LOM.

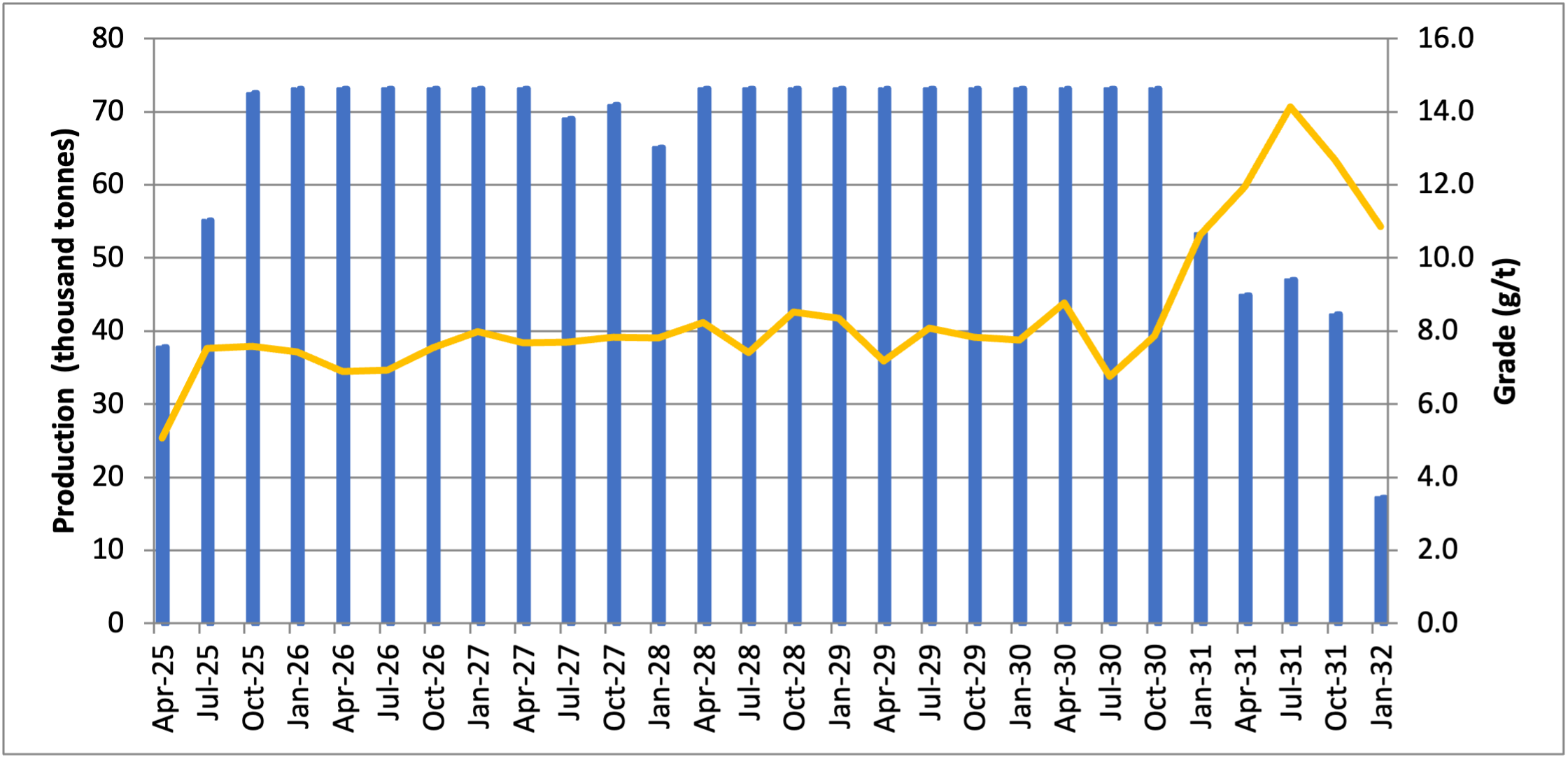

Figure 2: Average Annual Ore Production and Grade

Infrastructure

The Madsen Mine is adjacent to the community of Madsen, within the Red Lake Municipality of northwestern Ontario. Highway 618, a paved and provincially maintained road, connects the community and mine to the town of Red Lake 10 km to the northeast. Mining and mineral exploration is the primary industry in the Red Lake region; as a result, there is a full range of services and supplies for mineral exploration and mining and a strong pool of skilled labour.

All infrastructure needed to restart the Madsen Mine pursuant to this PFS plan is already in place. The mine has two underground access portals with ramps, over 21 km of modern underground development (from 2019 onward), a 1,275-metre shaft with a retrofitted and functional hoist mechanism, a processing facility with nameplate 1,089-tpd capacity built 2019-2020 (currently permitted for 800 tpd operations), a tailings facility also built 2019-2020 that saw a 4-foot dam lift in summer 2024, an office complex, a geology and core logging compound, and basic mine dry, maintenance, and warehouse facilities.

Further infrastructure projects currently underway include a 1.2-km tunnel that connects the two portals (on track for completion in March 2025), a 114-person workforce accommodations facility (on track for completion mid-February 2025), and a mine dry facility (on track for completion end February 2025).

The Madsen Mine is connected via a dedicated substation to the provincial hydroelectrical power grid and will access power at $0.12 per kilowatt hour.

Workforce

The Madsen Mine is expected to utilize a workforce of 221 people during steady state operations. There are currently approximately 140 workers employed, of which approximately 60% live locally.

Tailings and Mine Rock

Tailings will be managed through a combination of surface storage in the Tailings Management Facility (TMF) and underground deposition as hydraulic backfill. The TMF at the Madsen Mine is permitted to discharge tailings and will be expanded to manage a total of 1.6 Mt. The TMF is partitioned into two designated areas, Cell A and the Main TMF. Containment for the first four years of tailings deposition will be provided in Cell A, with the remainder of the tailings managed in the Main TMF.

Cell A is fully constructed and ready for operation, including a 4-meter dam raise that was completed in summer 2024.

The Main Dam will be constructed downstream of the existing polishing pond dams in year 4 to raise the perimeter crest elevation of the TMF and provide storage capacity for the remaining tailings. The two areas of the TMF offer sufficient capacity for supernatant ponds, surplus water storage, and flood water management.

Mine rock from underground development will be managed in the underground mine as backfill (42%) and stored in the existing mine rock management facility located adjacent to the TMF (58%). Multiple void historic stopes create good opportunity to store waste rock underground, thereby reducing costs.

Capital Expenditure

Modest expenditure requirement remains to get the Madsen Mine into production, slated for Q2 2025. Outstanding costs are modest because the historic Madsen Mine was rebuilt from 2019-2020, operating until late 2022 before shutting down. The rebuild established significant new infrastructure at the site, including the 800-tpd process plant, the West Portal, the tailings management facility, the water treatment plant, and 19 km of underground workings.

Since purchasing the Madsen Mine in June 2023, West Red Lake Gold has invested significant capital into projects the Company identified as necessary for a successful restart. This includes a 4-meter dam raise in Cell A of the TMF, a new primary crusher, the 1.2-km Connection Drift, a camp, a mine dry facility, many additions to the mining fleet, and over 2 km of underground workings.

Sustaining Capital

The mine requires $434 million in sustaining capital over its 7.2-year mine life, of which $9.1 million is closure and rehabilitation costs.

Mining development, additional equipment, replacement units, and major repairs make up the consistent parts of sustaining capital.

Rehabilitation of the Main Shaft and development of the East Shaft are the largest capital projects during the life of mine. West Red Lake Gold has already rehabilitated the hoisting mechanism in the headframe of the Main Shaft; the shaft itself now requires rehabilitation to be able to move material out of the mine starting in year 2. Year 1 see $22.5 million in sustaining capital allocated to this project.

The East Shaft is developed in years 3 and 4, at an estimated cost of $52 million. It will be raisebored once bottom access has been established via Madsen Main shaft, resulting in significant savings compared to blind sinking a shaft. During operations, mining generally follows the mineralized system northeast and downplunge. By year 4 the ventilation system centered on the Main Shaft is no longer sufficient and so a new vent raise is required. A cost-benefit analysis found a net savings in developing a skipping shaft, versus a simple vent raise, because it would cost approximately $20 per tonne to truck material to surface from the Madsen Deeps area versus approximately $4 per tonne to hoist material. This difference covers the $20 million additional cost of the full shaft over the vent raise, making the capital project a net benefit in this mine plan.

Beyond the PFS mine plan, the gold system at Madsen remains open at depth. Several deep historic intercepts returned good gold intercepts. If exploration is successful in defining resources downplunge of the reserves in this PFS, the East Shaft is well located to potentially render such resources economic to mine.

Operating Costs

Life of Mine (LOM) total operating cost is estimated at $322.67 per tonne of ore, as summarized in Table 2 below. The LOM total AISC is estimated to be US$1681 per oz. gold produced.

As noted in the Upside Potential section, the Company sees strong potential to create a more continuous reserve body, through this drilling work and through the practical application of a higher reserve cut-off grade.

Table 2: Operating Costs

| Mining | $212.93 per tonne |

| Processing | $75.25 per tonne |

| General & Administrative | $33.90 per tonne |

| Tailings | $0.59 per tonne |

| Total | $322.67 per tonne |

Financial Analysis

Using an average gold price of US$2317 per oz. and a US:CDN exchange rate of 1.4, the Madsen Mine project generates an after-tax NPV of $315 using 5% discount rate and an after-tax IRR of 255%.

The Project generates cumulative post-tax net cash flow of $391 million and average annual free cash flow of $69.5 million over the 6-year full production period.

Total taxes payable over the LOM at the assumed gold price are negligible because the combination of the significant tax losses that were acquired with the purchase of the project and the continued costs incurred on exploration and development cover the majority of the revenue considered in this mine plan.

Table 3: Key Operating, Cost, and Revenue Metrics

| Total | 2025 | 2026 | 2027 | 2028 | 2029 | 2030 | 2030 | 2032 | |

| Mill Throughput (kt) | 1,823 | 141.4 | 292.6 | 287.2 | 284.0 | 292.8 | 292.8 | 198.0 | 33.6 |

| Average Grade (g/t) | 8.16 | 8.2 | 7.2 | 7.8 | 8.0 | 7.9 | 7.8 | 11.7 | 6.0 |

| Production (kozs) | 457.9 | 35.3 | 63.6 | 67.7 | 70.0 | 70.8 | 70.8 | 73.2 | 6.4 |

| Gold Price (US$ per oz.) | $2317 (average) | $2,600 | $2500 | $2450 | $2200 | $2200 | $2200 | $2200 | $2200 |

| Net Revenue ($M) | $1,464.5 | $127.1 | $220.2 | $229.8 | $213.2 | $215.8 | $215.7 | $223.1 | $19.6 |

| Operating Costs ($M) | - $588.1 | - $57.1 | - $89.7 | - $87.1 | - $89.5 | - $88.3 | - $90.8 | - $72.8 | - $12.7 |

| Operating Cash Flow ($M) | $876.4 | $70.0 | $130.5 | $142.7 | $123.7 | $127.5 | $124.9 | $150.3 | $6.9 |

| Capital Expenditure + Working Capital ($M) | - $484.7 | - $90.4 | - $77.2 | - $91.8 | - $93.7 | - $58.5 | - $27.8 | - $28.3 | - $11.0 |

| Free Cash Flow ($M) | $391.8 | - $20.4 | $53.3 | $50.9 | $30.0 | $69.0 | $97.1 | $122.0 | -$4.2 |

| Average Annual Free Cash Flow (6 Full Production Years) ($M) | $69.5 | ||||||||

Table 4: Net Present Value ($M) Sensitivity to Gold Price, Opex, Capex

| -20% | -10% | 0% | 10% | 20% | |

| Gold Price | $68 | $192 | $315 | $407 | $496 |

| Opex | $388 | $352 | $315 | $267 | $218 |

| Capex | $382 | $349 | $315 | $272 | $229 |

Table 5: Net Present Value ($M) Sensitivity to US:CDN Exchange Rate

()[\]\\.,;:\s@\"]+)*)|(\".+\"))@((\[[0-9]{1,3}\.[0-9]{1,3}\.[0-9]{1,3}\.[0-9]{1,3}\])|(([a-zA-Z\-0-9]+\.)+[a-zA-Z]{2,}))$/;return b.test(a)}$(document).ready(function(){if(performance.navigation.type==2){location.reload(true)}$("iframe[data-lazy-src]").each(function(b){$(this).attr("src",$(this).attr("data-lazy-src"))});if($(".owl-article-body-images").length){$(".owl-article-body-images").owlCarousel({items:1,loop:true,center:false,dots:false,autoPlay:true,mouseDrag:false,touchDrag:false,pullDrag:false,nav:true})}var a=$("#display_full_text").val();if(a==0){$.ajax({url:"/ajax/set-article-cookie",type:"POST",data:{cmsArticleId:$("#cms_article_id").val()},dataType:"json",success:function(b){},error:function(b,d,c){}})}$(".read-full-article").on("click",function(d){d.preventDefault();var b=$(this).attr("data-cmsArticleId");var c=$(this).attr("data-productId");var f=$(this).attr("data-href");dataLayer.push({event:"paywall_click",paywall_name:"the_manila_times_premium",paywall_id:"paywall_article_"+b});$.ajax({url:"/ajax/set-article-cookie",type:"POST",data:{cmsArticleId:b,productId:c},dataType:"json",success:function(e){window.location.href=$("#BASE_URL").val()+f},error:function(e,h,g){}})});$(".article-embedded-newsletter-form .close-btn").on("click",function(){$(".article-embedded-newsletter-form").fadeOut(1000)})});$(document).on("click",".article-embedded-newsletter-form .newsletter-button",function(){var b=$(".article-embedded-newsletter-form .newsletter_email").val();var d=$("#ga_user_id").val();var c=$("#ga_user_yob").val();var a=$("#ga_user_gender").val();var e=$("#ga_user_country").val();if(validateEmail(b)){$.ajax({url:"/ajax/sendynewsletter",type:"POST",data:{email:b},success:function(f){$(".article-embedded-newsletter-form .nf-message").html(f);$(".article-embedded-newsletter-form .nf-message").addClass("show");setTimeout(function(){$(".article-embedded-newsletter-form .nf-message").removeClass("show");$(".article-embedded-newsletter-form .nf-message").html("")},6000);dataLayer.push({event:"newsletter_sub",user_id:d,product_name:"newsletter",gender:a,yob:c,country:e})},error:function(f,h,g){}})}else{$(".article-embedded-newsletter-form .nf-message").html("Please enter a valid email address.");$(".article-embedded-newsletter-form .nf-message").addClass("show");setTimeout(function(){$(".article-embedded-newsletter-form .nf-message").removeClass("show");$(".article-embedded-newsletter-form .nf-message").html("")},6000)}});$(document).on("click",".article-embedded-newsletter-form .nf-message",function(){$(this).removeClass("show");$(this).html("")});