SAG Holdings Limited

SAG Holdings Limited

SINGAPORE, Nov. 13, 2024 (GLOBE NEWSWIRE) -- SAG Holdings Limited ("SAG Holdings” or the "Company”), (Nasdaq: SAG), a Singapore-based provider of high-quality Original Equipment Manufacturer ("OEM”), third-party branded and in-house branded replacement parts for motor vehicles and non-vehicle combustion engines, today announced that Filtec Private Limited ("Filtec”), a wholly-owned subsidiary of SAG Holdings, has completed implementation of automation technology in its distribution center, embracing industrial innovation and leveraging advanced robotics and digital solutions to redefine its operations.

About Filtec

Specializing in filtration systems, lubricants, batteries, and heavy-duty diesel engine spare parts, Filtec serves key sectors such as marine, power generation, and transportation trucking. Recently relocated to Defu Industrial City, the company has turned its vision of a tech-driven, efficient operation into reality-a transformation catalyzed by the challenges and momentum of the COVID-19 era.

A Pioneering Push for Digital Transformation

Pre-COVID, digitalization was already a focus for Filtec. However, the pandemic significantly accelerated these efforts, with critical support from government agencies helping to fast-track change. Enterprise Singapore provided leadership training via the Enterprise Leadership for Transformation program at Singapore Management University, and the Infocomm Media Development Authority (IMDA) guided Filtec's team through design thinking workshops to identify and address key business challenges.

Through the Singapore Business Federation's Industry 4.0 Human Capital Initiative, in partnership with McKinsey and EY Singapore consultants, Filtec zeroed in on operational bottlenecks, particularly the labor-intensive pick-and-pack process. "This was a crucial area for improvement to enhance workflow, increase throughput, and enable scalability,” explained Jimmy Neo, CEO of SAG Holdings Limited. With high daily volumes in order processing, Filtec sought innovative solutions to meet demand while reducing manual errors.

Automation Through Robotics

Collaborating with Republic Polytechnic's Centre of Innovation for Supply Chain Management, Filtec implemented a warehouse management system (WMS) integrated with autonomous mobile robots (AMRs) for a goods-to-person picking system. The transition to robotics, though complex, yielded impressive efficiency gains. "The robots can move about 200 pieces per hour per workstation, reducing what was previously an eight-hour task to just two and a half hours,” shared Jamie Neo, communications and marketing manager at Filtec.

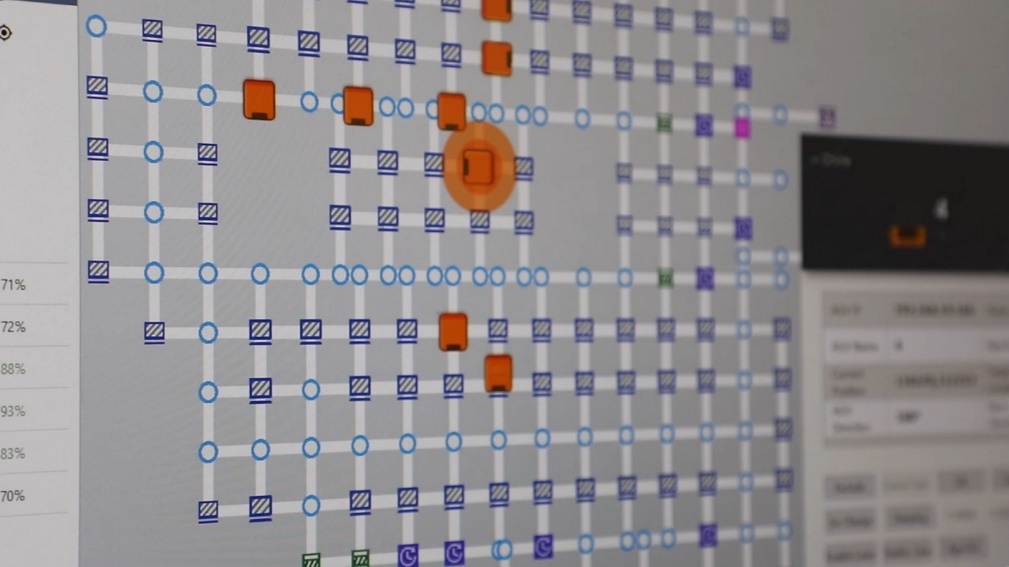

Figure 1: Filtec employs a total of 31 autonomous mobile robots in the Defu Industrial City facility

Bridging the Gap with Human-Centric Implementation

As Filtec modernizes, it remains committed to its workforce. Jamie Neo, a third-generation family member in the business, has been instrumental in integrating these changes. Jamie ensures that employees are at the heart of this evolution through regular feedback sessions and collaboration with external vendors. "Digitising is not just about moving from paper to screen; it's about making technology work for everyone, regardless of age,” Jamie said. To support employees, Filtec has invested in training programs to empower all team members to use these new tools effectively.

Figure 2: The movements of the autonomous mobile robots can easily be monitored using the system

Raising the Standard of Service and Talent Attraction

For Filtec, robotics is more than an operational improvement; it's a pathway to enhanced service standards and a draw for tech-savvy talent. "These high-tech solutions reduce errors and allow us to offer superior service to our clients and stakeholders,” noted Esther Tan from the sales and marketing department. Filtec's focus on reskilling ensures that traditional skills are preserved while integrating new competencies.

Looking Forward

Filtec's embrace of robotics in warehousing is only the beginning. Filtec is exploring data consolidation, developing an e-commerce platform, and enhancing last-mile delivery. Combining human capital with cutting-edge technology, this transformation reaffirms Filtec's position as a forward-thinking industry leader and a valued subsidiary of SAG Holdings Limited.

Filtec's transformation was recently profiled by JTC Corporation, formerly the Jurong Town Corporation, a statutory board under Singapore's Ministry of Trade and Industry that champions sustainable industrial development. The profile can be viewed at: https://www.jtc.gov.sg/about-jtc/news-and-stories/feature-stories/filtec.

About SAG Holdings

SAG Holdings is a leading Singapore-based distributor dedicated to supplying high-quality spare parts across a wide range of industries.

On-Highway Division: We provide an extensive range of genuine OEM and aftermarket parts for passenger vehicles, trucks, and buses. Our offerings include parts from manufacturers' brands, trusted third-party labels, and our in-house brands.

Off-Highway Division: Catering to industries like construction, marine, power generation, mining, and transportation, we offer specialized spare parts focusing on filtration systems, lubricants, batteries, and internal combustion engine components.

Our unwavering commitment to quality ensures customers experience maximum uptime, enhanced performance, and reduced total cost of ownership throughout the lifecycle of their machines. For more information, visit https://www.sag.sg.

Safe Harbor Statement

Statements in this press release about future expectations, plans and prospects, as well as any other statements regarding matters that are not historical facts, may constitute "forward-looking statements” within the meaning of The Private Securities Litigation Reform Act of 1995. These statements include, but are not limited to, statements relating to the expected trading commencement and closing dates. The words "anticipate,” "believe,” "continue,” "could,” "estimate,” "expect,” "intend,” "may,” "plan,” "potential,” "predict,” "project,” "should,” "target,” "will,” "would” and similar expressions are intended to identify forward-looking statements, although not all forward-looking statements contain these identifying words. Actual results may differ materially from those indicated by such forward-looking statements as a result of various important factors, including: the uncertainties related to market conditions and the completion of the public offering on the anticipated terms or at all, and other factors discussed in the "Risk Factors” section of the preliminary prospectus filed with the SEC. Any forward-looking statements contained in this press release speak only as of the date hereof, and SAG Holdings Limited specifically disclaims any obligation to update any forward-looking statement, whether as a result of new information, future events or otherwise, except as required by law.

Investor Relations Contact:

Matthew Abenante, IRC

President

Strategic Investor Relations, LLC

Tel: 347-947-2093

Email: [email protected]

Attachments