TAIPEI, Sept. 23, 2024 /PRNewswire/ -- With the development of artificial intelligence and the Internet of Things, traditional home appliances are gradually evolving toward intelligence. Among these, the smart upgrade of washing machines has significantly improved quality of life. Currently, washing machine manufacturers are integrating features such as intelligent washing, high efficiency and energy savings, large capacity, ultra-thin embedding, extremely quiet operation, and garment care functions into their core offerings to meet energy efficiency requirements, which poses greater challenges for motor control technology.

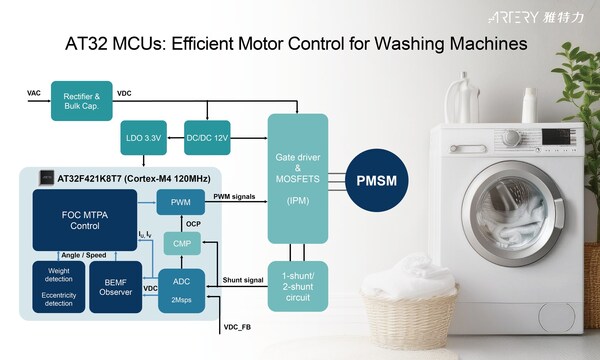

As the core of the motor control system, microcontrollers (MCUs) are responsible for handling various control requirements while delivering high performance. ARTERY's AT32 MCU family, with its exceptional performance and comprehensive motor development ecosystem, provides motor control solutions for washing machines, scooters, electric motorcycles, and other motor-driven products. These microcontrollers have already entered mass production.Efficient Drive Capability and Accurate Control

The AT32F421 series is designed to replace and enhance traditional Cortex®-M0/M3 based solutions. It adopts a high-speed mainstream platform based on the Cortex®-M4 architecture, integrating rich peripherals, fast and efficient algorithms, and offering high cost-performance to meet the needs of smart home appliances, motor control, and industrial automation. It is particularly well-suited for meeting the accuracy, efficiency, and safety requirements of washing machine motor control.

The AT32F421 series operates at a frequency of up to 120 MHz and features 64 KB of Flash memory and 16 KB of SRAM, allowing it to rapidly complete FOC (Field-Oriented Control) algorithms and current regulation. Its high PWM frequency and resolution ensure efficient and stable motor operation, further enhancing washing performance and energy savings. The AT32F421 series also includes a high-speed rail-to-rail input/output analog voltage comparator, which reduces the bill of materials (BOM) and provides overcurrent protection, enabling the washing machine to respond quickly to abnormal situations and safeguard both the product and the user.

In addition, the AT32F421 series embeds a high-speed 2 Msps 12-bit ADC, achieving a minimum sampling time of 54ns and a total conversion time of 0.5 μs at 28 MHz. This makes it ideal for one-shunt sensing drivers, as it can sample within a very short time window, making it highly suitable for washing machine control loop computations. The series provides high-frequency sampling rates in current, speed, and position control loops, ensuring stable and accurate operation of the washing machine.

High-Efficiency Motor Enhances Laundry Performance and User Experience

Direct Drive Control

The washing machine drive control solution based on the AT32F421 MCU utilizes DD (Direct Drive) technology, which connects the motor directly to the wash basket or drum instead of using traditional belt or gear drives. This enables efficient and accurate power transmission. This technology reduces energy loss, lowers running noise, and improves response speed and washing efficiency. The direct drive motor excels in controlling the washing cycle, ensuring clothes are thoroughly cleaned while extending the washing machine's service life.

Thanks to the compact design of the direct drive motor, the size of the washing machine can be minimized without compromising drum capacity. By eliminating the belt and pulley system, direct drive washing machines reserve more space for the drum and internal components, ensuring maximum washing capacity within the same machine size, making them an ideal choice for small homes.

Deep Field Weakening Control Algorithm

Since low to medium spin speeds dominate most washing cycles, motor designs typically focus on optimizing low-speed performance to balance torque and efficiency. However, dehydration speeds range from 800 to 1600 rpm, demanding a higher performance at higher speeds. Unlike traditional control strategies, the deep field weakening control algorithm used in the AT32F421 MCU-based washing machine solution adjusts Id and Iq in real time based on speed and load, ensuring a smooth increase in motor speed and eliminating abrupt changes during speed regulation. This innovation not only meets the high-speed, efficient, and stable operation required for the dehydration mode but also enhances the user experience by making the washing machine quieter and smoother during high-speed dewatering.

Automatic Weighing and Detection

Users require that washing machines automatically set the appropriate water level based on the weight of the clothes, helping to avoid unclean washing and unnecessary water and electricity costs. The AT32F421 MCU-based solution for washing machines provides high-performance CPU computing capabilities to automatically detect and calculate the weight of clothes using an algorithm that is significantly more accurate than industry standards. This reduces water waste while ensuring that clothes are thoroughly cleaned without damaging the fabric. Additionally, intelligent weighing is user-friendly-simply place the clothes in the drum and select the desired washing program.

Off-Balance Detection

Off-balance conditions caused by an unequal load during the spin cycle are a common problem. The AT32F421 MCU can detect unbalanced loads in real-time using sensors and algorithms, selecting appropriate control solutions based on the detection results. The washing machine can automatically adjust the washing program, such as re-balancing before dewatering or changing the water flow direction to reduce vibrations, ensuring stable operation. In addition, the AT32F421 MCU supports diagonal eccentricity detection as a supplement to traditional eccentricity detection, allowing for real-time monitoring and adjustment of eccentricity changes due to the movement of clothes during washing.

Motor Ecosystem

ARTERY provides a motor control algorithm library BSP package to build its motor control development ecosystem. This includes encoder, sensored/sensorless FOC sine-wave control mode, and six-step BLDC control, supporting Hall state self-learning, automatic identification of motor winding parameters, and current PI controller parameter auto-tuning. Its motor monitoring PC software features a user-friendly UI debugging interface, allowing users to monitor real-time motor running parameters, status, and dynamic waveforms to facilitate online tuning and debugging of control parameters. Such a powerful development toolkit and easy-to-use motor control algorithm library BSP package help developers create efficient motor control solutions, including square-wave drive, FOC sine-wave drive, Hall sensor feedback, and sensorless feedback. ARTERY's motor control development ecosystem improves the development efficiency of smart home appliance manufacturers, accelerates product mass production, and shortens time to market.

Furthermore, the AT32 MCU guarantees the safety of household appliances. ARTERY has obtained IEC 60730 certification for functional safety and provides a Class B software library to assist customers in product certification and cost-effectiveness. This significantly enhances the stability and security of the product at the hardware architecture level, laying a solid foundation for market access and consumer trust.