GANZHOU, China, July 22, 2024 /PRNewswire/ -- Farasis Energy proudly announces the successful testing of its revolutionary battery cells, marking a significant milestone in the quest for a million-mile battery-a feat achieved by only a few companies worldwide.

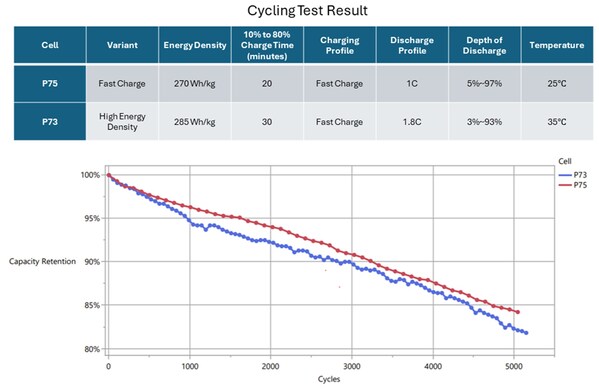

Achieving a million-mile battery requires cycling the cell over 5000 times, a process that takes 24 to 36 months of accelerated testing. Farasis Energy has rigorously tested its NCM chemistry cells, the P75 and P73, to evaluate their cyclic and calendar aging characteristics. These cells, developed since 2018, have undergone extensive testing and analysis, leading our engineers to confidently assert that battery packs using these cells can last a million miles over 15 years while retaining over 70% of their capacity.

Testing Under Real-World Conditions

The capacity degradation of cells depends on factors such as cell temperature, depth of discharge, charge rate, discharge rate, pressure, and storage temperature. Many cells perform well under industry-standard test conditions (25℃ and C/3 rate), but real-life conditions are rarely ideal. Farasis Energy's testing incorporated strenuous usage scenarios, including fast charging (equivalent to charging a battery from 10% to 80% in around 20 minutes for P75 and around 30 minutes for P73) and a high depth of discharge of 90% and above. Tests were conducted at varying temperatures (25 to 35℃) representative of major automotive markets like the coastal United States, Western Europe, and China. Additionally, our test fixtures emulate the variable pressure conditions encountered in real-life battery packs/modules, ensuring realistic testing conditions.

Advanced Materials and Technology

The long cycle life is achieved through advanced materials and charging strategies. The separators are coated with semi-solid gel to reduce the amount of electrolyte while ensuring excellent ion conductivity and chemical stability. The cathode and anode materials have excellent stability, and the electrolyte and electrode interface is optimized for improved performance. The charging strategy is optimized to reduce lithium plating and heat generation, effectively suppressing the side reactions that cause capacity loss.

High Energy Density and Safety Features

Battery packs with these cells not only offer long life but also high energy density, 20 to 30-minute fast charging, and thermal propagation mitigation. These cells are currently mass-produced for high-end passenger cars such as Voyah(the premium arm of State-owned Dongfeng)and Mercedes-Benz, as well as for commercial vehicles and other long-life applications. The cells achieve up to 285 Wh/kg energy density, providing an additional range of 300km for heavy-duty trucks compared to LFP-based battery packs.

Farasis has also developed unique packaging technologies to ensure safe operation. These technologies mitigate risks associated with thermal propagation by using a directional exhaust system, multisided thermal barrier protection for each cell, thermoelectric separation, and phase change materials to absorb heat during thermal events. These innovative measures effectively prevent the spread of thermal propagation, significantly enhancing cell-level safety.

Commercial Vehicle Applications

While only 1% of consumer vehicles reach 200,000 miles, commercial vehicles like buses, heavy-duty trucks, frequently achieve this milestone. Traditionally served by diesel engines, commercial vehicles can benefit from the lower operating costs of electric powertrains, which are half that of diesel engines when considering maintenance and fuel/electricity costs. Long-lasting battery packs in commercial vehicles provide significant financial and environmental benefits to operators and the public.

Top players in the electric vehicle takeoff and landing (eVToL) market have independently evaluated these cells, finding them to last over 10,000 flight cycles, thus choosing our pouch cells over cylindrical and prismatic cells.

For more detailed information, please contact us at [email protected]. Our team is eager to discuss how our million-mile battery technology can support your upcoming projects and applications.